Selection of system boundaries and organisation of the solution.

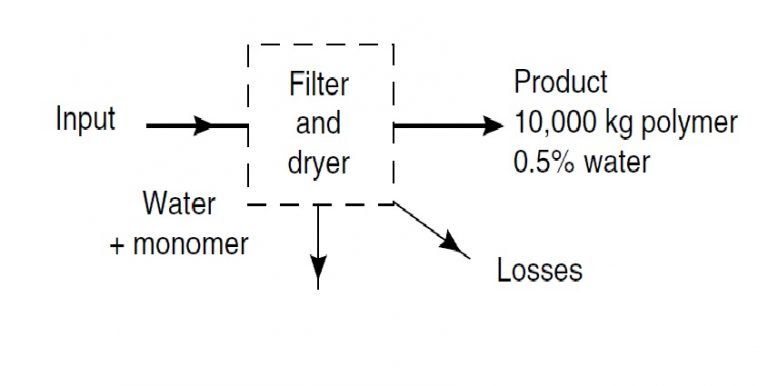

The diagram shows the main steps in a process for producing a polymer. From the following data, calculate the stream flows for a production rate of 10,000 kg/h.Reactor, yield on polymer 100 per cent

slurry polymerisation 20 per cent monomer/water

conversion 90 per cent

catalyst 1 kg/1000 kg monomer

short stopping agent 0.5 kg/1000 kg unreacted monomer

Filter, wash water approx. 1 kg/1 kg polymer

Recovery column, yield 98 per cent (percentage recovered)

Dryer, feed \sim 5 per cent water, product specification 0.5 per cent H_{2 }O

Polymer losses in filter and dryer \sim 1 per cent

Question 2.4: Selection of system boundaries and organisation of the solut...

The Blue Check Mark means that this solution has been answered and checked by an expert. This guarantees that the final answer is accurate.

Learn more on how we answer questions.

Learn more on how we answer questions.

Only those flows necessary to illustrate the choice of system boundaries and method of

calculation are given in the Solution.

Basis: 1 hour

Take the first system boundary round the filter and dryer.

With 1 per cent loss, polymer entering sub-system

=\frac{10,000}{0.99}=\underline{\underline{10,101} } kg

Take the next boundary round the reactor system; the feeds to the reactor can then be calculated.

At 90 per cent conversion, monomer feed

=\frac{10,101}{0.9}=\underline{\underline{11,223} } kg

Unreacted monomer = 11,223 – 10,101 = \underline{\underline{ 1122} } kg

Short-stop, at 0.5 kg/1000 kg unreacted monomer

= 1122 \times 0.5 \times 10^{-3} =\underline{\underline{ 0.6 } } kg

Catalyst, at 1 kg/1000 kg monomer

= 11,223 \times1 \times 10^{-3} =\underline{\underline{ 11 } } kg

Let water feed to reactor be F1, then for 20 per cent monomer

0.2=\frac{11,223}{F_{1}+ 11,223}

F_{1}=\frac{11,223\left(1-0.2\right) }{0.2} =\underline{\underline{44,892} } kg

Now consider filter-dryer sub-system again.

Water in polymer to dryer, at 5 per cent (neglecting polymer loss)

=10,101\times 0.05 =\underline{\underline{505} } kg

Balance over reactor-filter-dryer sub-system gives flows to recovery column.

water, 44,892 + 10,101 – 505 = \underline{\underline{54,448} } kg

monomer, unreacted monomer, = \underline{\underline{1122} } kg

Now consider recovery system

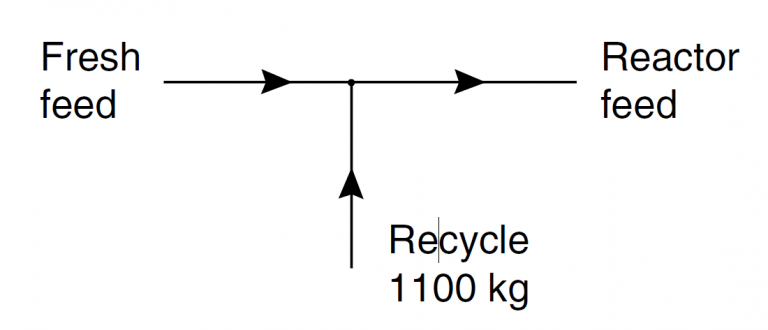

With 98 per cent recovery, recycle to reactor

= 0.98\times 1122 =\underline{\underline{1100} } kg

Composition of effluent 23 kg monomer, 54,488 kg water.

Consider reactor monomer feed

Balance round tee gives fresh monomer required

= 11,223-1100=\underline{\underline{10,123} } kg

Related Answered Questions

Reaction equation \ SO_{3} + H_{2} O \lon...

Basis: increment of time Δt

To illustrate the gene...

Basis: 100 mols feed (purge rate will be expressed...

Reaction: C_{2}H_{4}+ Cl_{2} \longrightarro...

Reactions: C_{2}H_{4}+ H_{2}O \longrightarr...

Basis: 5000 kg/h VC (the required quantity).

React...

Reaction: CH_{4}+ 2O_{2}\longrightarrow CO_...

Let the unknown quantities of the 20% slurry and w...