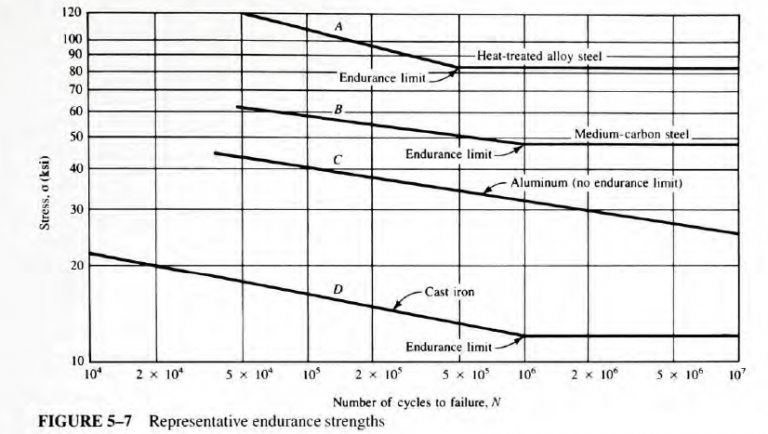

Determine the cumulative damage experienced by a ground circular rod, 1.50 in diameter, subjected to the combination of the cycles of loading and varying levels of reversed, repeated bending stress shown in Table 5-3. The bar is made from AISI 6150 OQT1100 alloy steel. The σ-N curve for the steel is shown in Figure 5-7, curve A for the standard, polished R. R. Moore type specimen.

| TABLE 5-3 Loading pattem for Example Problem 5-5 | |

| Stress level (ksi) |

Cycles n_i |

| 80 | 4000 |

| 70 | 6000 |

| 65 | 10000 |

| 60 | 25000 |

| 55 | 15000 |

| 45 | 1500 |