A cantilever beam made of cold drawn steel 20C8 \left(S_{u t}=540 N / mm ^{2}\right) is subjected to a completely reversed load of 1000 N as shown in Fig. 5.36. The notch sensitivity factor q at the fillet can be taken as 0.85 and the expected reliability is 90%. Determine the diameter d of the beam for a life of 10000 cycles.

Question 5.10: A cantilever beam made of cold drawn steel 20C8 (Sut = 540 N...

The Blue Check Mark means that this solution has been answered and checked by an expert. This guarantees that the final answer is accurate.

Learn more on how we answer questions.

Learn more on how we answer questions.

\text { Given } P=\pm 1000 N \quad S_{u t}=540 N / mm ^{2} .

q = 0.85 R = 90% N = 10 000 cycles.

Step I Selection of failure section

The failure will occur either at the section A or at the section B. At section A, although the bending moment is maximum, there is no stress concentration and the diameter is also more compared with that of the section B. It is, therefore, assumed that the failure will occur at the section B.

Step II Construction of S–N diagram

S_{e}^{\prime}=0.5 S_{u t}=0.5(540)=270 N / mm ^{2} .

\text { From Fig. } 5.24 \text { (cold drawn steel and } S_{u t}=\left.540 N / mm ^{2}\right) .

K_{a}=0.78 .

Assuming, 7.5 < d < 50 mm,

K_{b}=0.85 .

\text { For } 90 \% \text { reliability, } K_{c}=0.897 .

At the section B,

\left(\frac{D}{d}\right)=1.5 \text { and }\left(\frac{r}{d}\right)=0.25 .

\text { From Fig. } 5.5, \quad K_{t}=1.35 .

From Eq. (5.12),

K_{f}=1+q\left(K_{t}-1\right) (5.12).

K_{f}=1+q\left(K_{t}-1\right)=1+0.85(1.35-1)=1.2975 .

K_{d}=\frac{1}{K_{f}}=\frac{1}{1.2975}=0.771 .

S_{e}=K_{a} K_{b} K_{c} K_{d} S_{e}^{\prime} .

=0.78(0.85)(0.897)(0.771)(270)=123.8 N / mm ^{2} .

0.9 S_{u t}=0.9(540)=486 N / mm ^{2} .

\log _{10}\left(0.9 S_{u t}\right)=\log _{10}(486)=2.6866 .

\log _{10}\left(S_{e}\right)=\log _{10}(123.8)=2.0927 .

\log _{10}(10000)=4 .

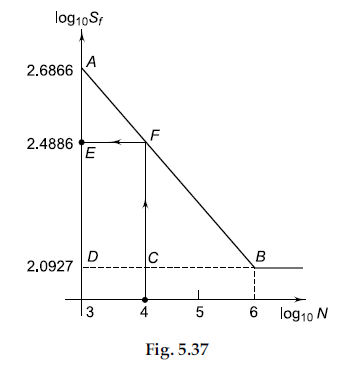

The S–N curve for this problem is shown in Fig. 5.37.

Step III Diameter of beam

From Fig. 5.37,

\overline{A E}=\frac{\overline{A D} \times \overline{E F}}{\overline{D B}}=\frac{(2.6866-2.0927)(4-3)}{(6-3)}=0.198 .

Therefore,

\log _{10} S_{f}=2.6866-\overline{A E}=2.6866-0.198=2.4886 .

S_{f}=308.03 N / mm ^{2} .

S_{f}=\sigma_{b}=\frac{32 M_{b}}{\pi d^{3}} .

d^{3}=\frac{32 M_{b}}{\pi S_{f}}=\frac{32(1000 \times 150)}{\pi(308.03)}.

d = 17.05 mm.

Related Answered Questions

\text { Given }\left(\sigma_{x}\right)_{\m...

\text { Given }\left(M_{t}\right)_{\max }=...

\text { Given } m=50 kg \quad h=25 mm \qua...

\text { Given } S_{u t}=660 N / mm ^{2} \q...

\text { Given } M_{t}=-100 N - m \text { t...

\text { Given } P=-50 N \text { to }+150 N...

\text { Given For vessel } D_{i}=500 mm [/...

Given For cantilever spring, d = 10 mm.

l=...

\text { Given } S_{u t}=600 N / mm ^{2} \q...

\text { Given } P=0 \text { to } P_{\max }...