A cantilever spring made of 10 mm diameter wire is shown in Fig. 5.46. The wire is made of stainless steel 4Cr18Ni10 \left(S_{u t}=860 N / mm ^{2}\right. and \left.S_{y t}=690 N / mm ^{2}\right) . The force P acting at the free end varies from 75 N to 150 N. The surface finish of the wire is equivalent to the machined surface. There is no stress concentration and the expected reliability is 50%. Calculate the number of stress cycles likely to cause fatigue failure.

Question 5.15: A cantilever spring made of 10 mm diameter wire is shown in ...

The Blue Check Mark means that this solution has been answered and checked by an expert. This guarantees that the final answer is accurate.

Learn more on how we answer questions.

Learn more on how we answer questions.

Given For cantilever spring, d = 10 mm.

l=500 mm \quad P=75 \text { to } 150 N \quad S_{u t}=860 N / mm ^{2} .

S_{y t}=690 N / mm ^{2} \quad R=50 \% .

Step I Endurance limit stress for cantilever beam

S_{e}^{\prime}=0.5 S_{u t}=0.5(860)=430 N / mm ^{2} .

From Fig. 5.24 (machined surface and S_{u t}=860 \left. N / mm ^{2}\right).

K_{a}=0.72 .

\text { For } 10 mm \text { diameter wire, } K_{b}=0.85 .

For 50% reliability,

K_{c}=1.0 .

S_{e}=K_{a} K_{b} K_{c} S_{e}^{\prime} .

=0.72(0.85)(1.0)(430)=263.16 N / mm ^{2} .

\left(M_{b}\right)_{\max .}=150 \times 500=75000 N – mm .

\left(M_{b}\right)_{\min .}=75 \times 500=37500 N – mm .

\left(M_{b}\right)_{m}=\frac{1}{2}\left[\left(M_{b}\right)_{\max .}+\left(M_{b}\right)_{\min .}\right] .

=\frac{1}{2}[75000+37500]=56250 N – mm .

\left(M_{b}\right)_{a}=\frac{1}{2}\left[\left(M_{b}\right)_{\max .}-\left(M_{b}\right)_{\min .}\right] .

=\frac{1}{2}[75000-37500]=18750 N – mm .

\sigma_{m}=\frac{32\left(M_{b}\right)_{m}}{\pi d^{3}}=\frac{32(56250)}{\pi(10)^{3}}=572.96 N / mm ^{2} .

\sigma_{a}=\frac{32\left(M_{b}\right)_{a}}{\pi d^{3}}=\frac{32(18750)}{\pi(10)^{3}}=190.99 N / mm ^{2} .

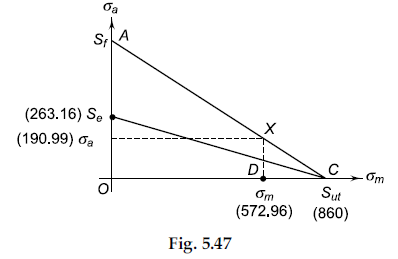

The modified Goodman diagram for this example is shown in Fig. 5.47. The point X with coordinates (572.96, 190.99) falls outside the region of safety.

This indicates a finite life for the spring. The value of S_{f} is obtained by joining C to X and then extending the line to the ordinate. Point A gives the value of S_{f}.

From similar triangles XDC and AOC,

\frac{\overline{X D}}{\overline{A O}}=\frac{\overline{D C}}{\overline{O C}} .

S_{f}=\overline{A O}=\frac{\overline{X D} \times \overline{O C}}{\overline{D C}}=\frac{190.99(860)}{(860-572.96)} .

=572.22 N / mm ^{2} .

Step III Construction of S–N diagram

0.9 S_{u t}=0.9(860)=774 N / mm ^{2} .

\log _{10}\left(0.9 S_{u t}\right)=\log _{10}(774)=2.8887 .

\log _{10}\left(S_{e}\right)=\log _{10}(263.16)=2.4202 .

\log _{10}\left(S_{f}\right)=\log _{10}(572.22)=2.7576 .

The S–N curve for this problem is shown in Fig. 5.48.

Step IV Fatigue life of cantilever spring From Fig. 5.48,

\overline{E F}=\frac{\overline{D B} \times \overline{A E}}{\overline{A D}}=\frac{(6-3)(2.8887-2.7576)}{(2.8887-2.4202)} .

=0.8395 .

\log _{10} N=3+\overline{E F}=3+0.8395=3.8395 .

N = 6910.35 cycles.

Related Answered Questions

\text { Given }\left(\sigma_{x}\right)_{\m...

\text { Given }\left(M_{t}\right)_{\max }=...

\text { Given } m=50 kg \quad h=25 mm \qua...

\text { Given } P=\pm 1000 N \quad S_{u t}...

\text { Given } S_{u t}=660 N / mm ^{2} \q...

\text { Given } M_{t}=-100 N - m \text { t...

\text { Given } P=-50 N \text { to }+150 N...

\text { Given For vessel } D_{i}=500 mm [/...

\text { Given } S_{u t}=600 N / mm ^{2} \q...

\text { Given } P=0 \text { to } P_{\max }...