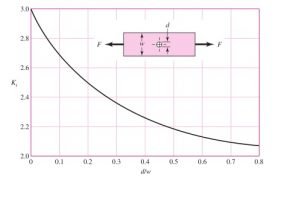

A strap to be made from a cold-drawn steel strip workpiece is to carry a fully reversed axial load F = LN \left(1000,120\right) lbf as shown in Fig. 6–39.

Consideration of adjacent parts established the geometry as shown in the figure, except for the thickness t.

Make a decision as to the magnitude of the design factor if the reliability goal is to be 0.999 95,athen make a decision as to the workpiece thickness t.