Steam enters a nozzle steadily at a specified flow rate and velocity. The inlet velocity of steam and the exit temperature are to be determined.

Assumptions 1 This is a steady-flow process since there is no change with time at any point and thus \Delta m_{CV} = 0 and \Delta E_{CV} = 0. 2 There are no work interactions. 3 The potential energy change is zero, \Delta pe = 0.

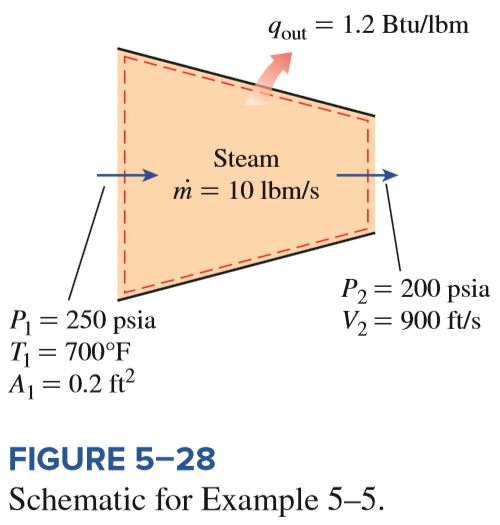

Analysis We take the nozzle as the system (Fig. 5–28). This is a control volume since mass crosses the system boundary during the process. We observe that there is only one inlet and one exit and thus \dot{m_{1}} = \dot{m_{2}} = \dot{m} .

(a) The specific volume and enthalpy of steam at the nozzle inlet are

\left.\begin{array}{l}P_{1}=250 \mathrm{psia} \\T_{1}=700^{\circ} \mathrm{F}\end{array}\right\} \begin{array}{l}v_{1}=2.6883 \mathrm{ft}^{3} / \mathrm{lbm} \\h_{1}=1371.4 \mathrm{Btu} / \mathrm{lbm}\end{array} (Table A–6E)

Then,

\begin{aligned}\dot{m} &=\frac{1}{v_{1}} V_{1} A_{1} \\10 \mathrm{lbm} / \mathrm{s} &=\frac{1}{2.6883 \mathrm{ft}^{3} / \mathrm{lbm}}\left(V_{1}\right)\left(0.2 \mathrm{ft}^{2}\right) \\V_{1} &=134.4 \mathrm{ft} / \mathrm{s}\end{aligned}

(b) Under stated assumptions and observations, the energy balance for this steady-flow system can be expressed in the rate form as

\begin{aligned}\underbrace{\dot{E}_{\mathrm{in}}-\dot{E}_{\mathrm{out}}}_{\begin{array}{c}\text {Rate of net energy transfer } \\\text { by heat, work, and mass }\end{array}} &=\underbrace{d E_{\mathrm{system}}/dt^{\nearrow{0 (steady)}}}_{\begin{array}{r}\text {Rate of change in internal, kinetic, } \\\text { potential, etc., energies }\end{array}}= 0 \\\dot{E}_{\mathrm{in}}&=\dot{E}_{\mathrm{out}}\\\dot{m}(h_{1}+\frac{V_{1}^{2}}{2})&=\dot{m}\left(h_{2}+\frac{V_{2}^{2}}{2}\right) \quad \text { (since } \dot{Q} \cong 0, \dot{W}=0, \text { and } \Delta \mathrm{pe} \cong 0)\end{aligned}

Dividing by the mass flow rate\dot{m} and substituting, h_{2} is determined to be

\begin{aligned} h_{2} &= h_{1} – q_{out} – \frac{V_{2}^{2} – V_{1}^{2}}{2}\\&=( 1371.4 – 1.2)Btu / lbm – \frac{(900 ft/s)^{2} – (134.4 ft/s)}{2} (\frac{1 Btu / lbm}{25,037 ft^{2}/s^{2}})\\&=1354.4 Btu / lbm \end{aligned}

Then,

\left.\begin{array}{l}P_{2}=200 \mathrm{psia} \\h_{2}=1354.4 Btu / lbm\end{array}\right\}\begin{array}{l}T_{2}=662.0^{\circ} \mathrm{F}\end{array} (Table A–6E)

Discussion Note that the temperature of steam drops by 38.0°F as it flows through the nozzle. This drop in temperature is mainly due to the conversion of internal energy to kinetic energy. (The heat loss is too small to cause any significant effect in this case.)